Dixon Pipe and Welding Fittings

Dixon Straub Open-Flex 1L Couplings

Vendor: Dixon Pipe and Welding Fittings

Coupling Type: Valves, Flow Control, & Strainers

Description:

For permanent Repair

Coupling Category:

Valves

Straub Open-Flex 1L couplings are suitable for repairing or joining pipes where access to the pipe end is difficult or not possible.

This unique wrap-around design differs from similar type repair products because the installation or repair is permanent due to

the unique flexible lipseal gasket design. Open-Flex couplings will also act as an expansion joint. Straub Open-Flex couplings

do require the pipes to be properly anchored and restrained as they are not pull-out resistant like the Straub Grip-L couplings.

Use Straub Open-Flex couplings to replace bolted sleeve type couplings (AWWA Std. C-219) or for permanent repairs or

installation.

Assembly tool available, STR6648.

|

Specifications:

Approvals:

|

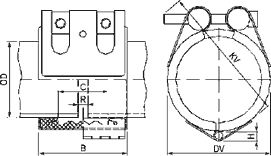

| Size | Pipe OD | Working Pressure | Coupling Dimensions | Assembled Dimensions | Maximum

Distance Between Pipe End |

Weight

(lbs) |

Stainless Steel | ||||

| actual | range

min to max |

PSI | B | C | H | DV | KV | R | Part # | ||

| 1-1/2" | 1.90" | 1.85" to 1.95" | 363 | 3.0" | 1.4" | .28 | 2.8" | 3.3" | .20" | 1.10 | STR35001 |

| 2" | 2.38" | 2.32" to 2.42" | 232 | 3.0" | 1.4" | .28 | 3.2" | 3.7" | .20" | 1.34 | STR35151 |

| 2-1/2" | 2.88" | 2.81" to 2.93" | 232 | 3.0" | 1.4" | .36 | 3.2" | 3.7" | .20" | 1.80 | STR35201 |

| 3" | 3.50" | 3.44" to 3.56" | 232 | 3.7" | 2.0" | .36 | 4.4" | 4.9" | .20" | 2.10 | STR35351 |

| 4" | 4.50" | 4.43" to 4.57" | 232 | 3.7" | 2.0" | .36 | 5.4" | 5.9" | .20" | 2.33 | STR35651 |

| 5" | 5.56" | 5.49" to 5.57" | 232 | 4.2" | 2.4" | .38 | 6.4" | 7.1" | .20" | 3.20 | STR35901 |

| 6" | 6.63" | 6.54" to 6.71" | 232 | 4.2" | 2.4" | .38 | 7.5" | 8.1" | .20" | 3.70 | STR36051 |

|

Not pull-out resistant.

Ensure that pipes are properly anchored and supported. |

Assembly tool available, STR6648.

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov |