Waterblast Hose

JGB Enterprises is known for delivering high quality, reliable products for virtually every application, and there is no exception for Waterblast Hose.

All of our Waterblast Hoses are 100% tested and certified. We are also a member of the WJTA - WaterJet Technology Association.

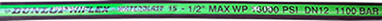

Dunlop Waterblast Hoses

JGB carries Dunlop Hiflex high performance Waterblast Hoses for use in many waterblast applications such as paint removal, hydro-demolition of concrete, tank cleaning and much more. They are offered in 3 pressure series with color coded branding for easy identification. All have a safety factor of 2.5:1 and conform to RMA standards.

Very High Pressure Waterblast Hose

Tube: Black water resistant synthetic rubber

Cover: Black oil and water resistant synthetic rubber

Reinforcement: 4 Spiral Layers

Temperature: -40°F to 160°F

| Series | ID | OD | WP | Burst Pressure | Bend Radius | Weight LB/FT |

| WB10 | 1/2” | 0.969” | 10000 | 25000 | 8.00” | 0.61 |

| WB10 | 1” | 1.528” | 10000 | 25000 | 14.00” | 1.46 |

| Series | ID | OD | WP | Burst Pressure | Bend Radius | Weight LB/FT |

| WB15 | 3/8” | 0.843” | 18000 | 45000 | 6.00” | 0.57 |

| WB15 | 1/2” | 1.000” | 16000 | 40000 | 8.00” | 0.85 |

| WB15 | 3/4” | 1.252” | 14500 | 36250 | 11.00” | 1.20 |

Ultra High Pressure Waterblast Hose

Tube: Black water resistant synthetic rubber

Cover: Black oil and water resistant synthetic rubber

Reinforcement: 6 Spiral Layers

Temperature: -40°F to 160°F

| Series | ID | OD | WP | Burst Pressure | Bend Radius | Weight LB/FT |

| WB20 | 1/2” | 1.161” | 20000 | 50000 | 8.00” | 1.17 |

Manuli Rubber Goldenblast Hoses

JGB offers Manuli Goldenblast Waterblast Hoses with 4 and 6 steel spiral reinforcements. They have a safety factor of 2.5:1 and conform to RMA standards. These hoses are designed to be used for scale removing operations needing extremely high working pressures:

- building and industrial sectors (roadworks, removal of concrete from reinforced concrete structures safeguarding metal components)

- scale removal ships hulls in shipyard

- dust elimination

All 3 hoses have covers that resist abrasion, ozone and high temperatures.

What is Waterblasting?

Waterblasting is an alternative to Sand Blasting, Shot Blasting or other methods of cleaning or removing old materials.

Application

Designed for very high and ultra-high pressure waterblasting:- Surface Preparation

- Pavement Maintenance

- Paint Removal

- Corrosion and dust removal

- Welding residue, drawing compounds removal

- Abrasive Jet Cutting of Hard Materials

- Water Jet Cutting of food and soft materials

- WaterJets Texture Sandstone

- Hydrodemolition of Concrete

- Tank Cleaning

- Building and industrial sectors (roadworks, removal of concrete from reinforced concrete structures safeguarding metal components)

- Scale removal ships hulls in shipyard

Why use Waterblasting?

- Environmentally friendly

- Reduces hazardous waste

- Eliminates air pollution

- Eliminates damage to nearby structures

- Removes invisible or unseen contamination

- Keeps the original profile of the surface that is being cleaned

Other reasons for choosing Waterblasting:

- 30-35% less time required using Waterblast Hose

- 40% maintenance savings

- Six times more nozzle life

- Cutting speed 100% faster

- A 2000:1 return on investment

JGB Enterprises is a proud member of the WJTA - WaterJet Technology Association