Thread Sealing Tips

Thread Sealing Tips

Sealing NPT threads can be an exasperating experienceif certain techniques are not followed. The following tips will help alleviate many common problems in thread sealing:

- Always use some type of sealant (tape or paste) and apply

sealant to male thread only. If using a hydraulic sealant, allow

sufficient curing time before system is pressurized.

- When using tape sealant, wrap the threads in a clockwise motion

starting at the first thread and, as layers are applied, work

towards the imperfect (vanishing) thread. If the system that

the connection being made to cannot tolerate foreign matter (i.e.

air systems), leave the first thread exposed and apply the tape

sealant as outlined above.

- When using paste sealant, apply to threads with a brush, using

the brush to work the sealant into the threads. Apply enough

sealant to fill in all the threads all the way around.

- When

connecting one stainless steel part to another stainless steel

part that will require future disassembly, use a thread sealant

that is designed for stainless steel . This stainless steel

thread sealant is also useful when connecting aluminum to aluminum

that needs to be disconnected in the future. These two materials

gall easily, and if the correct sealant is not used, it can

be next to impossible to disassemble.

- When connecting parts made of dissimilar metals (i.e. steel and aluminum), standard tape or paste sealant performs satisfactory.

- For sizes 2" and below, tape or paste performs satisfactory.

When using thread tape, four wraps (covering all necessary

threads) is usually sufficient.

- For sizes 2½" and above, thread paste is recommended.

If thread tape is used, eight wraps (covering all necessary

threads) is usually sufficient. Apply more wraps if necessary.

- For stubborn to seal threads, apply a normal coating of thread paste followed by a normal layer of thread tape. 9. For extremely stubborn to seal threads, apply a normal coating of thread paste followed by a single layer of gauze bandage followed by a normal layer of thread tape.

Caution!When this procedure is done, the connection becomes permanent. Extreme measures will be necessary to disconnect these components. All other measures to seal the threads should be explored prior to use of this technique.

- Over-tightening threads can be just as detrimental as in sufficient tightening. For sizes 2" and below, hand tighten the components and, with a wrench, tighten 3 full turns. For sizes 2½" and above, hand tighten the components and, with a wrench, tighten 2 full turns.

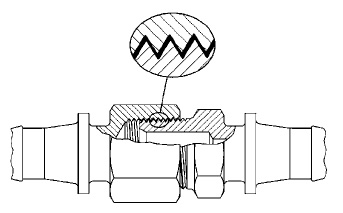

Thread Seal Type

- A seal is obtained by applying a sealant to the male

thread before engaging. - The sealant is used to prevent spiral leakage.

- Thread tape or paste is the preferred sealant in this type of

application.

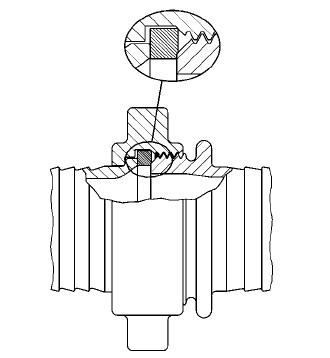

Washer Seal Type

- A seal is obtained when the male thread is tightened

down onto the washer of the female assembly. - The washer should be inspected regularly and replaced as

needed to prevent leakage.

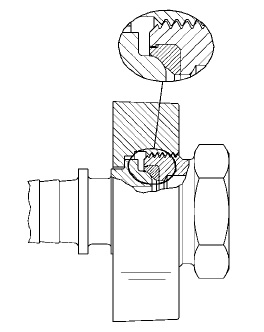

Mechanical Seal Type

- A seal is obtained through metal to metal contact or metal

to seal contact, i.e. JIC couplings have a metal

to metal seal. Boss Ground Joint couplings have a metal to seal contact, (shown above). - The couplings should be retightened as needed to

prevent leakage.