Ham-Let Product Lines

LET-LOK® Tube Fittings

The LET-LOK range of connectors has been developed to fill the rapidly increasing demand for tube fittings suitable for high pressure use in environments such as petrochemical, fluid, power, nuclear, electronic,as well as other major industries.

LET-LOK tube fittings have been carefully manufactured and tested to withstand the demands of high performance tube fittings, such as high pressure, impulse, vibration, vacuum and temperature. These tube fittings are manufactured to exacting tolerances using the most modern and advanced computerized automation.

How LET-LOK® Fittings Work

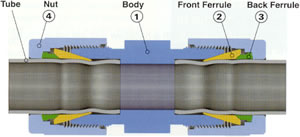

LET-LOK tube fittings are composed of four parts:

- Body

- Front ferrule

- Back ferrule

- Nut

The LET-LOK tube fitting is a mechanism used for both sealing and gripping tubing. Through mechanical advantage and geometry the fitting produces a leak-tight assembly.

Fitting Assembly

To assemble, simply insert the tube into the complete assembly until the tube bottoms-out against the shoulder of the fitting body. The two ferrules are driven forward between the nut and fitting body using the mechanical force created by rotating the nut clockwise.

The back ferrule (3) is driven against the tapered rear of the front ferrule (2) and the front ferrule is driven by force into the tapered mouth of the body. The rear ferrule is swaged radially inwards on the tube while lifting the front ferrule out to form a full faced seal on the tapered surface of the body.

The 1 1/4 turn on the nut from the hand tight position assures consistent drive of the sealing members. This ensures an effective seal against high pressure as well as ultra high vacuum conditions.

Thank you to The HAM-LET Valve & Fitting Company. Source material HAM-LET Catalog. Any errors in the transcription of this data are solely the responsibility of JGB Enterprises, Inc. No warranty, including implied warranty of merchantability, fitness for a particular purpose, or other warranty of quality is either expressed or implied of this product.