Basic Hose Construction

Cover

The cover is the outermost or visible area of the hose. It is designed to

be a protective covering against wear, abrasion, cuts, weather,

and the general destructive action encountered in normal service.

Body or Carcass

The body reinforcement is the supporting structure of the hose. It can range from simple to complex combinations and consists of cord, yarn, fabric, wire, or any combination of these.

Tube or lining

The tube is the innermost element of a hose and is compounded to provide resistance to the material being carried. With the wide range of rubber compounds available, a hose can be built to withstand abrasive materials, chemicals, oil and a wide variety of other materials.

The Four Basic Methods of Hose Construction

Although Goodyear/Veyance Technologies makes more than 2000 types of hose for specialized applications, there are only 4 basic construction methods used. Since each of these 4 methods embodies certain fundamental characteristics that make it particularly suitable for certain functions, an understanding of these methods may assist you in making the best use of this catalog.

Keep in mind that a reference to anyone of these types of construction will imply all the characteristics and benefits outlined here plus specific features attained through the proper compounding of rubber, choice materials, and variation in plies and thickness to ensure that each hose is exactly right for the job it is designed for.

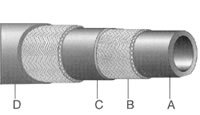

TYPE 1: Vertical Braided Hose

Entire hose length cured in one operation.

B. Seamless reinforcing braids of synthetic textile wire, or other material- applied by high speed vertical or horizontal braiders.

C. Rubber layers between braids establish positive bond between braids when vulcanized.

D. Extruded, seamless cover.

Advantages: Flexible. High resistance to kinking. Cover either smooth or wrapped. Available in long continuous lengths. Excellent tensile strength.

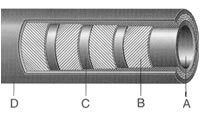

TYPE 2: Spiral Hose

Built by machine with either textile or wire cord reinforcement applied so that each ply is laid at a given angle for maximum dimensional stability.

B. Reinforcement of synthetic textile wire or other material.

C. Rubber layers between reinforcement plies to establish positive bond.

D. Cover.

Advantages: Extremely flexible. Smooth bore, uniform tube. High strength with long length capability.

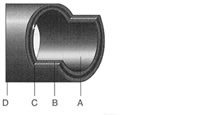

TYPE 3: Hand Built Spiraled Ply Hose

Built by hand on a mandrel. Cured under pressure applied from outside by cloth wraps and steam.

B. Tailor-made spiral wrapped fabric

C. Wire reinforcement where needed.

D. Cover stock of selected gauge and compound. Wrap cured.

Advantages: Craftsman-built to special requirements. Wide variation in sizes, constructions, and materials. Built-in strength to fit most rugged job requirements. Couplings, fittings, nipples, flanges and beaded ends can be built in. Available in lengths up to 50 feet, in sizes up to 18 inches. On larger diameters, consult JGB.

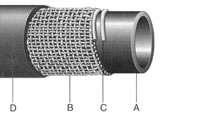

TYPE 4: Knitted Hose

B. Seamless woven textile jacket.

C. Interwoven wire helix reinforcement where needed.

D. Extruded seamless cover.

Thank you to Goodyear/Veyance Technologies Tire & Rubber company. Source material Goodyear/Veyance Technologies Catalog #99-130. Any errors in the transcription of this data are solely the responsibility of JGB Enterprises, Inc. No warranty, including implied warranty of merchantablility, fitness for a particular purpose, or other warranty of quality is either expressed or implied of this product.