OPW Engineered Systems

OPW Epsilon Coupling System

Vendor: OPW Engineered Systems

Coupling Type: Cam & Groove Couplings

Description:

Prevents Spills and Reduces Fugitive Emissions of VOCs

Coupling Category:

Epsilon®

EPSILON® is a low spill coupling, based on a double ball valve system integrating a sophisticated safety design in sizes of 3/4", 1", 1-1/2", 2" and 3". The design is constructed to handle a pressure of 435 psi (30 Bar) and temperature up to 450°F (230°C) and is available with end connections complying to ANSI and DIN standards.

All wetted materials are 316/316L stainless steel (1.4401/1.4404) with TFM or PFA seals. Hastelloy® C is also available for use with more aggressive fluids.

Beyond the common advantages of a ball valve design, EPSILON® provides for flow through an unrestricted flowpath and double shut off reliability in the coupling connection.

SUPERIOR FLOW: Unrestricted flow path provides less than 1psi pressure drop at 150 GPM.

SAFETY: EPSILON® coupling is equipped with safety interlocks, which force the valves to open and close only with a deliberate action, preventing accidental opening of the valve.

ENVIRONMENT: EPSILON® is a low spill system, specified to less than .40 ml spillage for the 2" coupling (2000 cycles test average 0.6 ml) and less than 1/10th of a teaspoon (half an eyedropper).

MAINTENANCE: EPSILON® was not only engineered for easy operations, but also for quick replacement of the transfer seal without any lockout. No special tools are required for replacement of seals.

Epsilon® Applications

- Bulk Storage

- In-plant Processing

- Reactor Units

- Filtration Units

- Tank Car

- Rail Car

Features

- Spring-energized TFM or PFA U-cup sealing

- Male and female lug and flange connection interfaces

- Independent and multi-level safety interlocks

- Polyurethane dust cap or Stainless Steel pressure cap

- Available in 3/4", 1", 1-1/2", 2" and 3"

- Available in Stainless Steel and Hastelloy®

- FDA-compliant seal materials

Benefits

-

Dry Disconnect Reliability

- low spill face seal reduces amount of loss upon disconnect -

Enhanced Environmental Compliance

- Positive shut-off of coupling halves eliminates line contamination and accidental release of potentially hazardous fluids into the environment during connection and disconnection. -

Full Flow

- Straight-through flow path provides unrestricted flow in either direction, minimizing pressure drop. -

Unparalleled Safety

- Multiple safety interlocks eliminate unintentional spills and catastrophic chemical releases that threaten worker safety and the environment. -

Prevents Cross-Contamination

Optional keyed couplings mechanically lock out and isolate transfer lines.

Male and Female Lug and Flange Connection Interfaces

Ramped lug and flange interfaces are first aligned and then connected with a push, followed by a quarter (90°) turn. This "instant" connection method is done by hand without tools in order to create compression on the critical interface seal.

Concave/Convex Full-Flow Shut-Off Valve

A convex ball nests in a concave ball to virtually eliminate any cavity between the mating halves. The positive shutoff ball valves, and the absence of a cavity between them, minimize chemical loss when the coupling is disconnected. Each half is an independently operated, positive shut-off ball valve that is controlled by manually rotating the valve handles. The straight-through EPSILON® valve design also provides unrestricted, high flow in either direction and low pressure drop. All metal wetted components are 316 stainless steel or Hastelloy®.

Independent and Redundant Safety Interlocks

EPSILON® technology involves five independent and redundant mechanical interlocks. They require deliberate sequential action by users, thereby eliminating unintentional spills and catastrophic chemical releases that threaten worker safety and the environment.

Spring-Energized and Spring-Loaded PTFE U-Cup Sealing

A spring-energized stem and face and flange seal provide initial sealing. The spring supplies all the load required for sealing when the media pressure is too low to fully actuate the lips of the seal. Testing confirms the low spillage and emission specifications are still achieved after 2,000 cycles.

Ultra Low Spill Face Seal (Optional)

This seal reduces the amount of spillage

at disconnect to .2 cc. This seal is not

pressure assisted and should only be used

for applications lower than 100 psi.

Cavity Filled (Optional)

Designed to reduce the possibility of contamination

by entrapment of process fluid in the void normally

found behind the ball and the valve body. Ideal

for applications where cross-contamination and

cleanliness is a concern. Back side of the valve

balls are bored for efficient cleaning.

Polyurethane Dust Cap

Used to protect the ball from damage and debris

when coupling is closed and disconnected.

Stainless Steel/Hastelloy Pressure Cap

Used to increase the level of safety when coupling

is closed, disconnected and under operating

pressure.

Transportation Coupling System (TCS)

Specially designed for railcar, truck, isotainer or

tote equipment used in transporting chemicals

safely. Contact JGB for more information.

Keyed Couplings

For extremely critical operations, EPSILON®

offers the unique keyed interface which locks

out and isolates transfer lines, preventing

cross-contamination.

Designed for Maintainability

OPW Engineered Systems’ EPSILON® design

allows for easy maintenance. Seals, stems and

bearings can be replaced easily to keep the

connections performing like new.

Approvals

EPSILON® couplings are approved/listed for pressure

service through a comprehensive set of international

agencies.

Consult JGB for specific details for your

application.

TFM - Standard Seal

Next generation PTFE with best combination of

temperature ranging from -22°F (-30°C) to 450°F

(230°C), sealing, and sliding characteristics.

PFA - Available Consult JGB

Transportation Coupling System (TCS)

Specially designed for railcar, truck, isotainer or tote

equipment used in transporting chemicals safely. Contact

OPW Engineered Systems for more information.

Dual Ball Race (Optional)

-

Radial swivel seal

-Replaces dynamic face seal

- Lower leak rate

- Lower seal mortality rate caused by over-compressing seal to install bearings -

Dual ball races with hardened stainless bearings

- Replaces PTFE sleeve bearing that may become overloaded and allow greater axial misalignment causing the dynamic face seal to leak

- Provides additional support for applications with long hose drops or high load requirements. - Spring energized dust seal

WARNING: Due to the variety of chemicals that these couplings may be used to transfer, the user is responsible to verify the compatibility of the coupling body and the seal materials with the chemical being conveyed.

Performance Characteristics

| Valve Size | Port Size | Spillage | Maximum Emissions | Flow Rate GPM (l/min) | CV | Max Working Pressure psi (bar) | Weight - lbs (kg) Adapter Coupler | Temp = °F (°C) Min Max | ||

| 1-inch | 3/4”, 1”, DN 20 or DN 25 Port | <0.7 ml | <25 ppm | 50 (189) | 42 | 435 (30) | 2.7 (1.2) | 3.0 (1.4) | -22°F (-30°C) | 450 (230) |

| 2-inch | 1-1/2”, 2”, DN 40 or DN 50 Port | <0.6 ml | <25 ppm | 150 (568) | 160 | 435 (30) | 4.0 (1.8) | 6.0 (2.7) | -22°F (-30°C) | 450 (230) |

| 3-inch | 3” or DN 80 Port | <2 ml | <25 ppm | 300 (1135) | 240 | 360 (25) | 16.0 (7.3) | 19.0 (8.6) | -22°F (-30°C) | 450 (230) |

Valve Size

EPSILON® couplings can be attached to hose or pipe sizes ranging from 3/4" to 3" or DN 20 to DN 80. There are three different valve body sizes that are machined to accept the different sizes and different connection types.

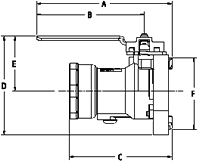

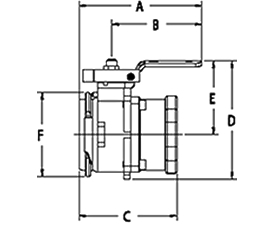

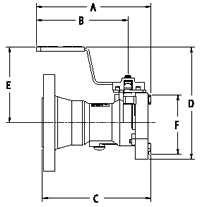

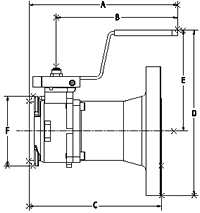

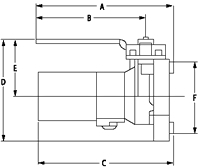

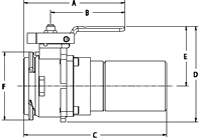

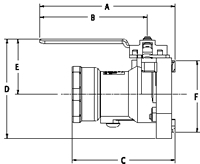

Ordering Specifications

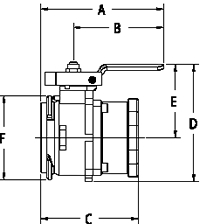

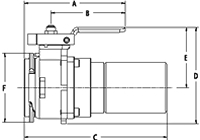

| Sl. No. |

Type | Size | End Connection | Dimensional Data - inch | |||||

| A | B | C | D | E | F | ||||

| 1 | COUPLER HALF, NPT | 1" | 3/4" | 4.5 | 3.4 | 4.3 | 4.4 | 2.7 | 3.0 |

|

1" | 1" | 4.5 | 3.4 | 4.3 | 4.4 | 2.7 | 3.0 | |

| 2" | 1 1/2" | 6.9 | 5.5 | 5.3 | 5.1 | 2.8 | 3.7 | ||

| 2" | 2" | 6.9 | 5.5 | 5.3 | 5.1 | 2.8 | 3.7 | ||

| 3" | 3" | 8.6 | 6.5 | 8.1 | 7.7 | 4.4 | 5.0 | ||

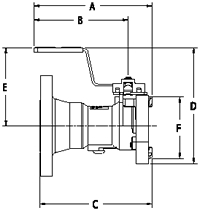

| 2 ADAPTOR HALF, NPT | 1" | 3/4" | 4.3 | 3.4 | 3.3 | 4.2 | 2.6 | 2.7 | |

|

1" | 1" | 4.3 | 3.4 | 3.3 | 4.2 | 2.6 | 2.7 | |

| 2" | 1 1/2" | 4.8 | 3.5 | 3.8 | 4.5 | 2.8 | 3.3 | ||

| 2" | 2" | 4.8 | 3.5 | 3.8 | 4.5 | 2.8 | 3.3 | ||

| 3" | 3" | 8.5 | 6.5 | 5.5 | 7.0 | 4.5 | 4.6 | ||

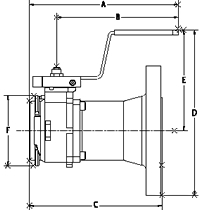

| 3 COUPLER HALF, FLANGED 150 LBS ANSI | 1" | 3/4" | 4.7 | 3.6 | 5.7 | 5.7 | 3.9 | 3.0 | |

|

1" | 1" | 4.7 | 3.6 | 5.7 | 5.7 | 3.9 | 3.0 | |

| 2" | 1 1/2" | 7.1 | 5.7 | 5.8 | 6.9 | 4.7 | 3.7 | ||

| 2" | 2" | 7.1 | 5.7 | 5.9 | 6.9 | 4.7 | 3.7 | ||

| 3" | 3" | 8.6 | 6.5 | 9.5 | 7.7 | 4.4 | 5.0 | ||

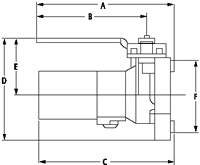

| 4 ADAPTOR HALF, FLANGED 150 LBS ANSI | 1" | 3/4" | 4.5 | 3.6 | 5.4 | 5.8 | 3.8 | 2.7 | |

|

1" | 1" | 4.5 | 3.6 | 5.4 | 6.0 | 3.8 | 2.7 | |

| 2" | 1 1/2" | 6.9 | 5.7 | 5.5 | 7.2 | 4.7 | 3.3 | ||

| 2" | 2" | 6.9 | 5.7 | 5.5 | 7.7 | 4.7 | 3.3 | ||

| 3" | 3" | 8.4 | 6.4 | 8.2 | 8.9 | 5.2 | 4.6 | ||

| 5 COUPLER HALF, BUTT WELD SCHEDULE 40 |

1" | 3/4" | 4.5 | 3.4 | 6.1 | 4.4 | 2.6 | 3.0 | |

|

1" | 1" | 4.5 | 3.4 | 6.1 | 4.4 | 2.6 | 3.0 | |

| 2" | 1 1/2" | 6.9 | 5.5 | 6.8 | 5.1 | 2.8 | 3.7 | ||

| 2" | 2" | 6.9 | 5.5 | 6.8 | 5.1 | 2.8 | 3.7 | ||

| 3" | 3" | 8.7 | 6.5 | 9.7 | 7.7 | 4.4 | 5.0 | ||

| 6 ADAPTOR HALF, BUTT WELD SCHEDULE 40 |

1" | 3/4" | 4.3 | 3.4 | 6.3 | 4.2 | 2.6 | 2.7 | |

|

1" | 1" | 4.3 | 3.4 | 6.3 | 4.2 | 2.6 | 2.7 | |

| 2" | 1 1/2" | 4.8 | 3.5 | 7.1 | 4.5 | 2.8 | 3.3 | ||

| 2" | 2" | 4.8 | 3.5 | 6.8 | 4.5 | 2.8 | 3.3 | ||

| 3" | 3" | 8.5 | 6.5 | 6.6 | 6.9 | 4.4 | 4.6 | ||

| 7 COUPLER HALF, BSP | 1" | G 3/4" | 114.81 | 86.87 | 108.46 | 112.52 | 67.31 | 76.20 | |

|

1" | G 1" | 114.81 | 86.87 | 108.46 | 112.52 | 67.31 | 76.20 | |

| 2" | G 1 1/2" | 175.77 | 139.70 | 133.60 | 128.78 | 71.63 | 93.47 | ||

| 2" | G 2" | 175.77 | 139.70 | 133.60 | 128.78 | 71.63 | 93.47 | ||

| 3" | G 3" | 217.42 | 164.34 | 204.72 | 194.82 | 112.27 | 126.75 | ||

| 8 ADAPTOR HALF, BSP | 1" | G 3/4" | 109.47 | 86.87 | 84.07 | 106.17 | 66.04 | 68.58 | |

|

1" | G 1" | 109.47 | 86.87 | 84.07 | 106.17 | 66.04 | 68.58 | |

| 2" | G 1 1/2" | 121.16 | 88.90 | 96.27 | 115.32 | 72.14 | 82.55 | ||

| 2" | G 2" | 121.16 | 88.90 | 96.27 | 115.32 | 72.14 | 82.55 | ||

| 3" | G 3" | 214.88 | 164.34 | 139.19 | 176.78 | 113.28 | 116.84 | ||

| 9 COUPLER HALF, FLANGED DIN PN40 | 1" | DN20 | 119.63 | 91.69 | 145.29 | 143.76 | 98.81 | 76.20 | |

|

1" | DN25 | 119.63 | 91.69 | 144.53 | 143.76 | 98.81 | 76.20 | |

| 2" | DN40 | 179.58 | 143.51 | 147.83 | 175.77 | 118.62 | 93.47 | ||

| 2" | DN50 | 179.58 | 143.51 | 148.59 | 175.77 | 118.62 | 93.47 | ||

| 3" | DN80 | 217.42 | 164.34 | 241.05 | 194.82 | 112.27 | 126.75 | ||

| 10 ADAPTOR HALF, FLANGED DIN PN40 | 1" | DN20 | 114.30 | 91.69 | 137.92 | 146.56 | 97.28 | 68.58 | |

|

1" | DN25 | 114.30 | 91.69 | 137.16 | 151.13 | 97.28 | 68.58 | |

| 2" | DN40 | 175.77 | 143.51 | 139.70 | 182.63 | 119.13 | 82.55 | ||

| 2" | DN50 | 175.77 | 143.51 | 140.46 | 195.33 | 119.13 | 82.55 | ||

| 3" | DN80 | 213.36 | 163.07 | 208.03 | 226.06 | 130.81 | 116.84 | ||

| 11 COUPLER HALF, WELD END DIN 2559 |

1" | 20 | 114.30 | 86.87 | 154.94 | 111.51 | 66.29 | 76.20 | |

|

1" | 25 | 114.30 | 86.87 | 154.94 | 111.51 | 66.29 | 76.20 | |

| 2" | 40 | 175.77 | 139.70 | 173.48 | 128.78 | 71.63 | 93.47 | ||

| 2" | 50 | 175.77 | 139.70 | 173.48 | 128.78 | 71.63 | 93.47 | ||

| 3" | 80 | 221.23 | 164.34 | 245.62 | 194.82 | 112.27 | 126.75 | ||

| 12 ADAPTOR HALF, WELD END DIN 2559 |

1" | DN20 | 109.47 | 86.87 | 159.26 | 106.17 | 66.04 | 68.58 | |

|

1" | DN25 | 109.47 | 86.87 | 159.26 | 106.17 | 66.04 | 68.58 | |

| 2" | DN40 | 121.16 | 88.90 | 181.36 | 115.32 | 72.14 | 82.55 | ||

| 2" | DN50 | 121.16 | 88.90 | 172.97 | 115.32 | 72.14 | 82.55 | ||

| 3" | DN80 | 214.88 | 164.34 | 167.13 | 176.02 | 112.52 | 116.84 | ||

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov |