OPW Engineered Systems

OPW Drylock Dry Disconnect Coupling

Vendor: OPW Engineered Systems

Coupling Type: Cam & Groove Couplings

Description:

Designed to safely transfer hazardous corrosive, volatile liquids such as acids, solvents and petrochemicals.

Coupling Category:

Drylok™

Drylok™ is designed to safely transfer hazardous corrosive, volatile liquids such as acids, solvents and petrochemicals. An interlocking handle averts accidental spills by preventing uncoupling while the valve is open. And, the unit’s flat face minimizes fluid loss, further reducing exposure to risk during operation. Drylok™ is ideal for all kinds of hazardous fluids where product loss is a problem, such as high-pressure lines, high flow rates, slurries, and gases.

Benefits

- One of the driest disconnects in the industry - less than 1/2 ml of fluid loss from a 2" unit (less than .10 teaspoon).

- Unprecedented safety - meets or exceeds all of today’s stringent emission and worker safety requirements set by EPA, OSHA, and others. Drylok™ cannot be uncoupled while the valve is open.

- Optimum flow rate - less obstruction in easy-flow interior optimizes the flow rate in high-pressure or high-viscosity applications.

- Ease of use - simple handle action connects valve to coupler and opens and closes the flow. 360° orientation ensures proper seating and alignment. No clamps, clips, loops or tabs that can cause operator error.

Features

- Available in 1", 2" and 3" sizes

- Standard O-ring seals for longevity, low cost and ease of maintenance

- Super-Pak Adjustable packing with V-type material provides a continuous compression, emission-free seal on handle shaft. (2"& 3" only)

- Available in 316 Stainless Steel, Alloy 20® or Hastelloy® C with NPT, BSP, ANSI Flanged, BW, and SW end connections

- AAR Approved

- CRN Approved

Super-Pak valve seal system on 2" and 3" models.*

*Super-Pak valve seal is a V-Type 75% PTFE and graphite blend, pressure energized packing. The packing nut can be tightened to stop leaks and emissions.

| Type | Number | Size | Weight |

|---|---|---|---|

| Coupler | 5770 | 1" | 2-1/4 lbs./1.0 kg |

| 2" | 10-1/4 lbs./4.6 kg | ||

| 3" | 14-1/2 lbs./6.5 kg | ||

| Adaptor | 5670 | 1" | 1-1/4 lbs./.6 kg |

| 2" | 7-1/2 lbs./3.4 kg | ||

| 3" | 11-3/4 lbs./5.3 kg |

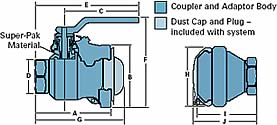

Dimensions

| Size | A | B | C | D | E | F | G | H | I | J | Connected |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1" | 3-21/64" 85.6mm | 2-15/32" 62.7mm | 5-3/8" 136.5mm | 1-7/8" 47.6mm | 6-3/4" 171.5mm | 4-37/64" 116.3mm | 3-33/64" 89.3mm | 2-5/32" 54.9mm | 3-3/16" 81mm | 3-3/4" 95.3mm | 6-1/16" 153.9mm |

| 2" | 6-3/16" 173mm | 5" 127mm | 6" 152.4mm | 2-3/4" 69.9mm | 8-3/8" 212.7mm | 7-1/4" 184.2mm | 7-7/32" 183.4mm | 5" 127mm | 4-15/16" 125.4mm | 5-5/16" 134.9mm | 10-1/6" 255.5mm |

| 3" | 7-3/4" 196.9mm | 6-3/16" 157.2mm | 8-3/4" 222.3mm | 4" 101.6mm | 12" 304.8mm | 8-31/32" 227.8mm | 8-49/64" 197.3mm | 5-1/2" 139.7mm | 6-7/8" 174.6mm | 7-17/64" 184.7mm | 13-3/8" 339.7mm |

Pressure Rating

When connected to the adaptor, the Drylok™ Coupler can be opened and closed against a maximum of 150 psi head pressure.Ordering Specification

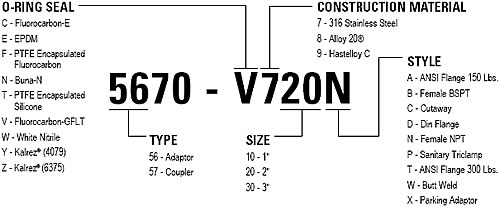

To assure that your order is processed promptly, please specify quantity, product number, size, construction materials and give a brief description of the product. Use the convenient product numbering system (below) to simplify your selections. Please consult JGB for any design or special requirement you may need or desire.

| How To Order - Use this example as your guide to determine the part number of the Drylok™ coupling you need. Part numbers indicate coupling type, O-ring seal material, construction material and size. |

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov |