Dixon Valves

Dixon Pneumatically Actuated Stainless 3 Piece Ball Valves

Description:

Spring Return (normally closed) - Double Acting

Coupling Category:

Valves

|

3-Piece Stainless Ball Valve

|

Rack and Pinion Actuator

|

- CF8M body and ball

- 15% glass reinforced RTFE seats

- blow-out proof stainless steel stem

- live-loaded stem packing

- ISO 5211 mounting pad

- swing out in-line easy maintenance

- 1/2" - 2" rated to

1000 PSI

WOG;

3" rated to

800 PSI

WOG

- temperature range:

-40°F

to

400°F

|

- hard anodized aluminum body

- nickel plated anti-blowout pinion

- Buna-N O-rings

- NAMUR mounting

- bi-directional stops for ±5° travel adjustment

- 80 PSI plant air required

- visual position indication

- maximum operating pressure:

120 PSI

- operating temperature range:

-40°F

to

200°F

- tested to one million cycles

|

Spring Return (normally closed)

|

Double Acting

|

|

|

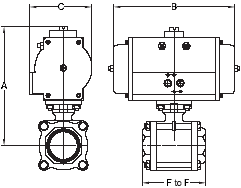

| Dimensions are approximate.

Engineering dimensions are available upon request. Specifications are subject to change without notice. |

| Size |

F to F |

A |

B |

C |

Stainless Steel |

| Part # |

| 1/2" |

2.6 |

7.0 |

7.7 |

3.2 |

BV2IG-05011-BBC 1 |

| 3/4" |

3.0 |

7.2 |

7.7 |

3.2 |

BV2IG-07511-BBC 1 |

| 1" |

3.4 |

6.1 |

7.7 |

3.2 |

BV2IG-10011-BBC |

| 1-1/4" |

4.0 |

6.3 |

7.7 |

3.2 |

BV2IG-12511-BBC |

| 1-1/2" |

4.7 |

7.7 |

8.1 |

3.7 |

BV2IG-15011-BBC |

| 2" |

5.2 |

8.8 |

8.1 |

3.7 |

BV2IG-20011-BBC |

| 3" |

7.2 |

10.2 |

9.8 |

4.7 |

BV2IG-30011-BBC |

1 bracket and coupler required for 1/2" and 3/4" spring return actuator

|

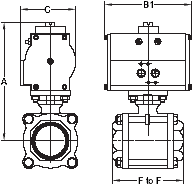

| Size |

F to F |

A |

B1 |

C |

Stainless Steel

|

| Part #

|

| 1/2" |

2.6 |

5.0 |

4.7 |

2.4 |

BV2IG-05011-BCC |

| 3/4" |

3.0 |

5.2 |

4.7 |

2.4 |

BV2IG-07511-BCC |

| 1" |

3.4 |

6.1 |

5.7 |

3.2 |

BV2IG-10011-BCC |

| 1-1/4" |

4.0 |

6.3 |

5.7 |

3.2 |

BV2IG-12511-BCC |

| 1-1/2" |

4.7 |

7.7 |

5.9 |

3.7 |

BV2IG-15011-BCC |

| 2" |

5.2 |

8.0 |

5.9 |

3.7 |

BV2IG-20011-BCC |

| 3" |

7.2 |

10.2 |

7.2 |

4.7 |

BV2IG-30011-BCC |

|

|

A wide variety of switches, solenoids, positioners, etc., are available. Contact JGB for

details. |

|

|

|

Caution! |

|

|

Even though there are torque safety factors built into our automated ball valve packages, actual service conditions

must also be considered when selecting the proper product for the appropriate application.

For example: Severe service conditions such as dirty water, dirty air, all slurries, raw sewage water, oils, and other viscous fluids can

have a dramatic affect in raising the torque requirements of ball valves as much as 75% and therefore larger actuators may be required.

Please consult JGB when dealing with these types of applications.

|

|

|